Metaplas: 3D-Printed Multi-Polymers

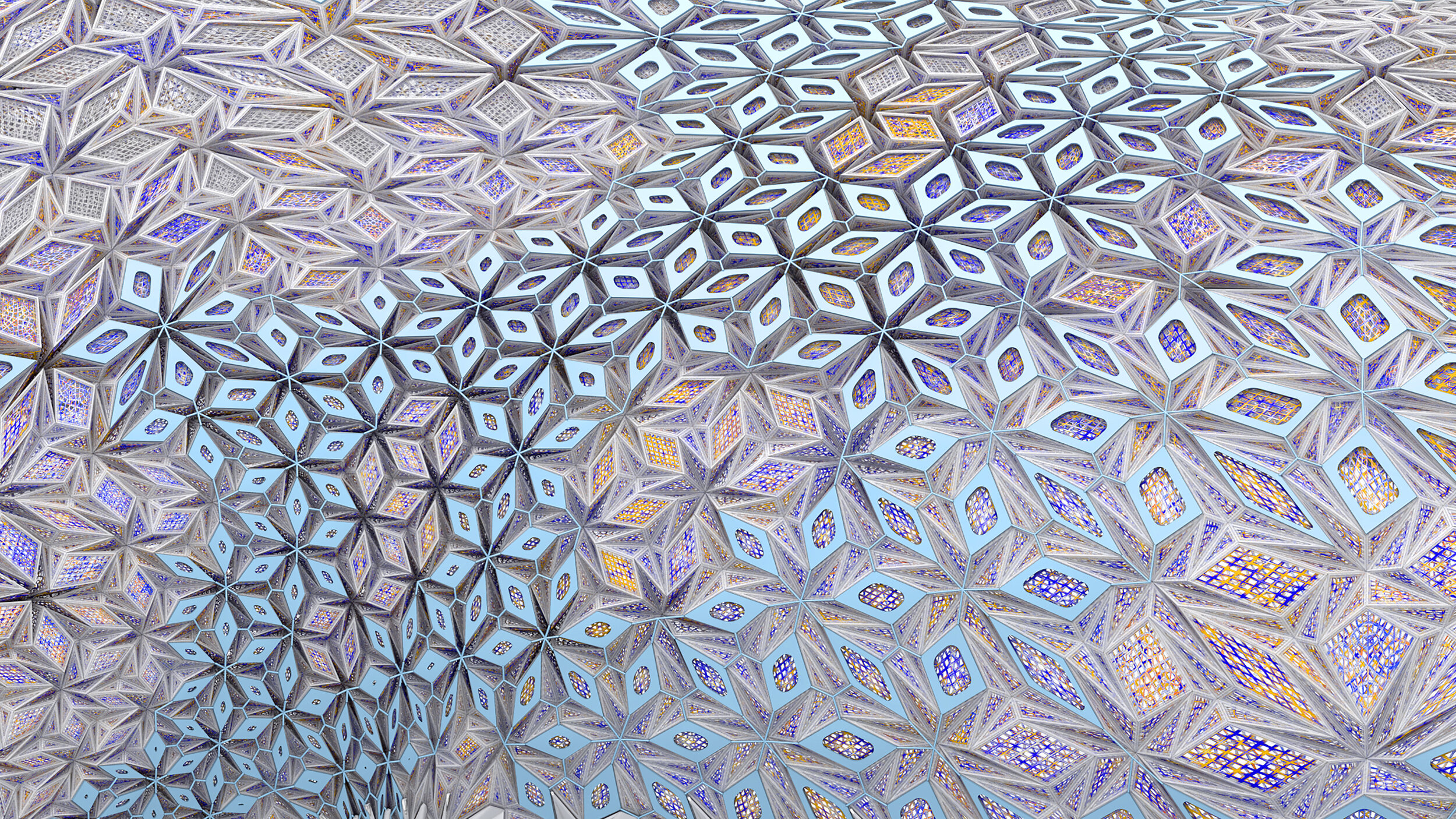

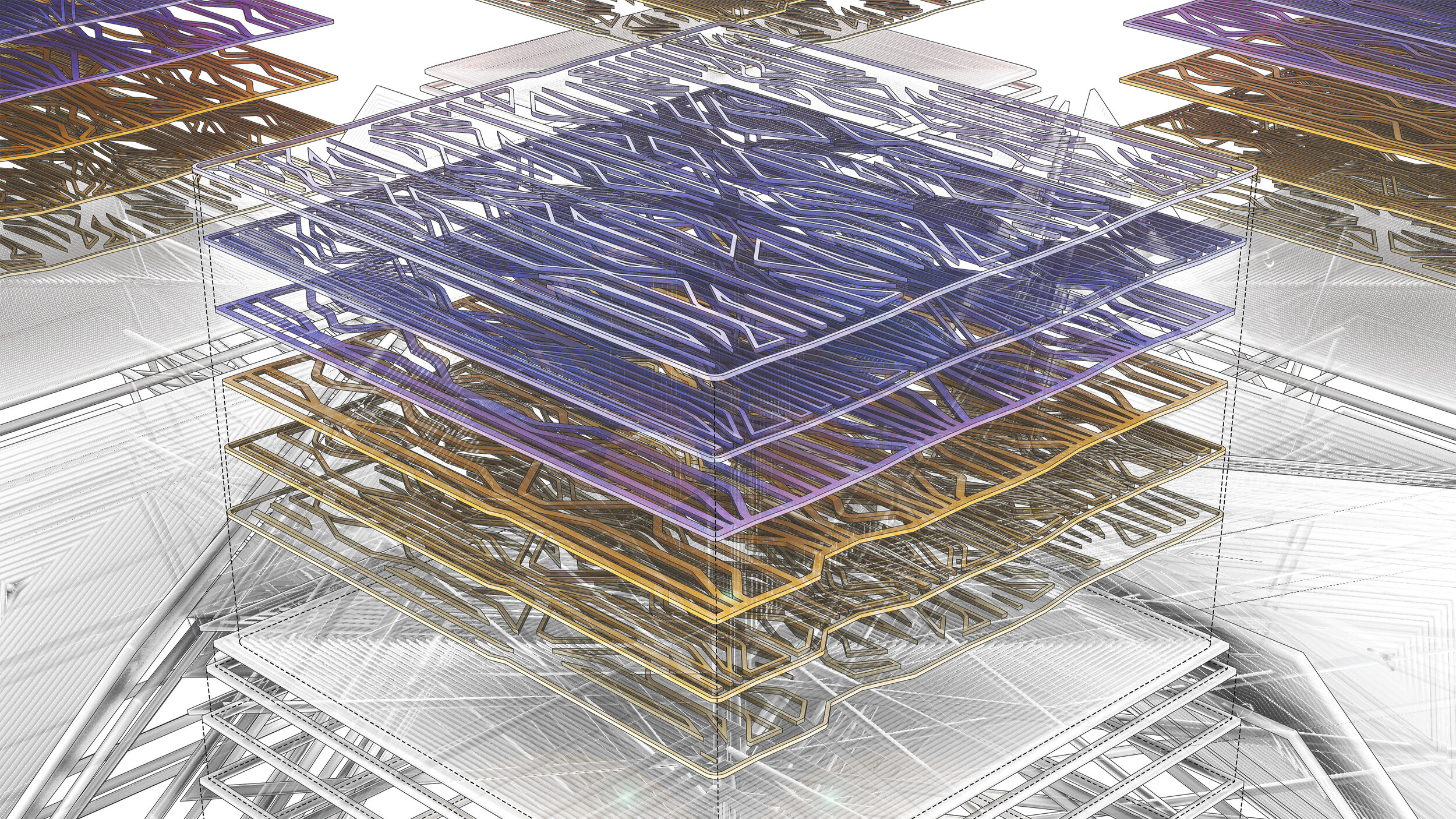

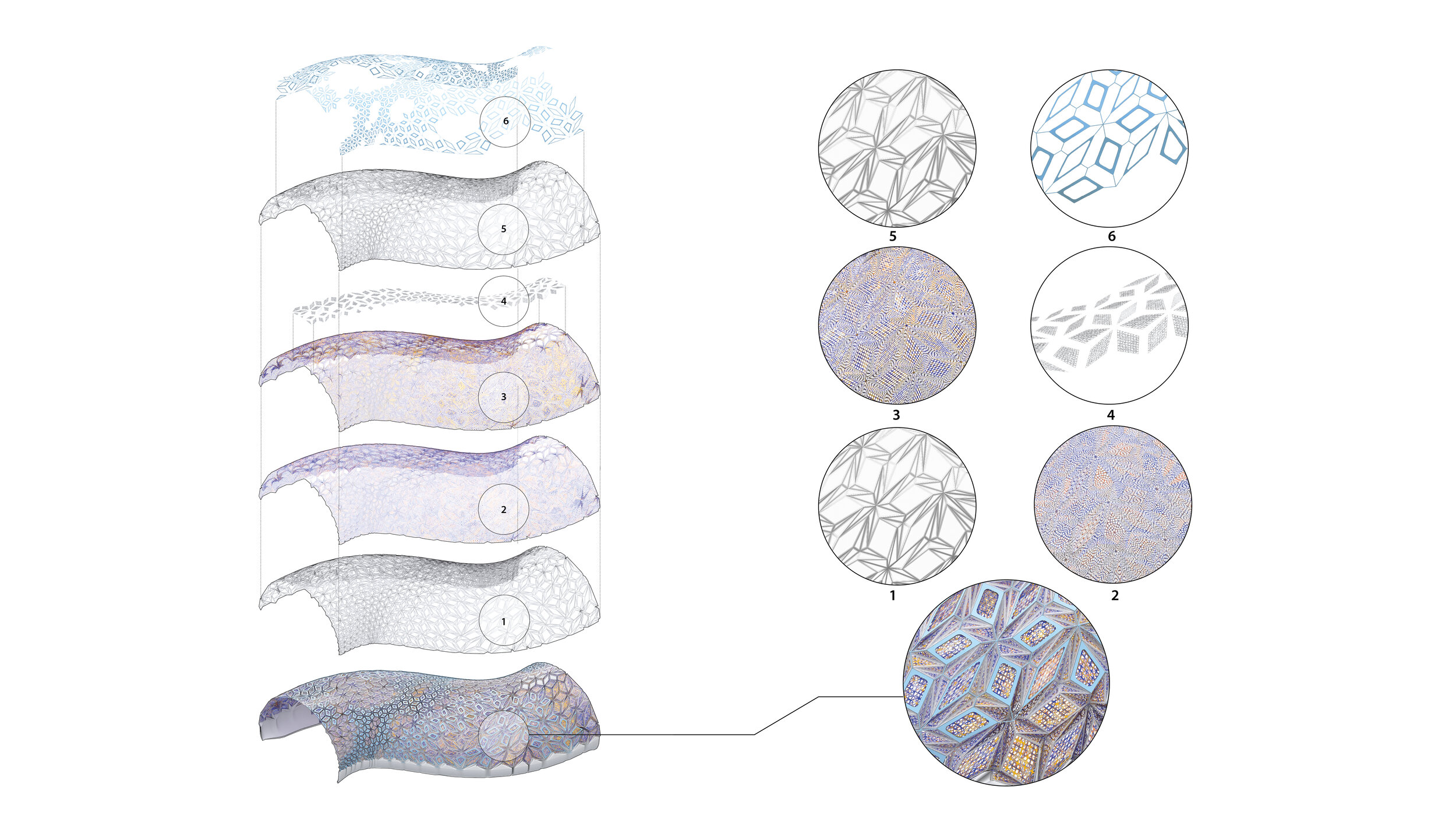

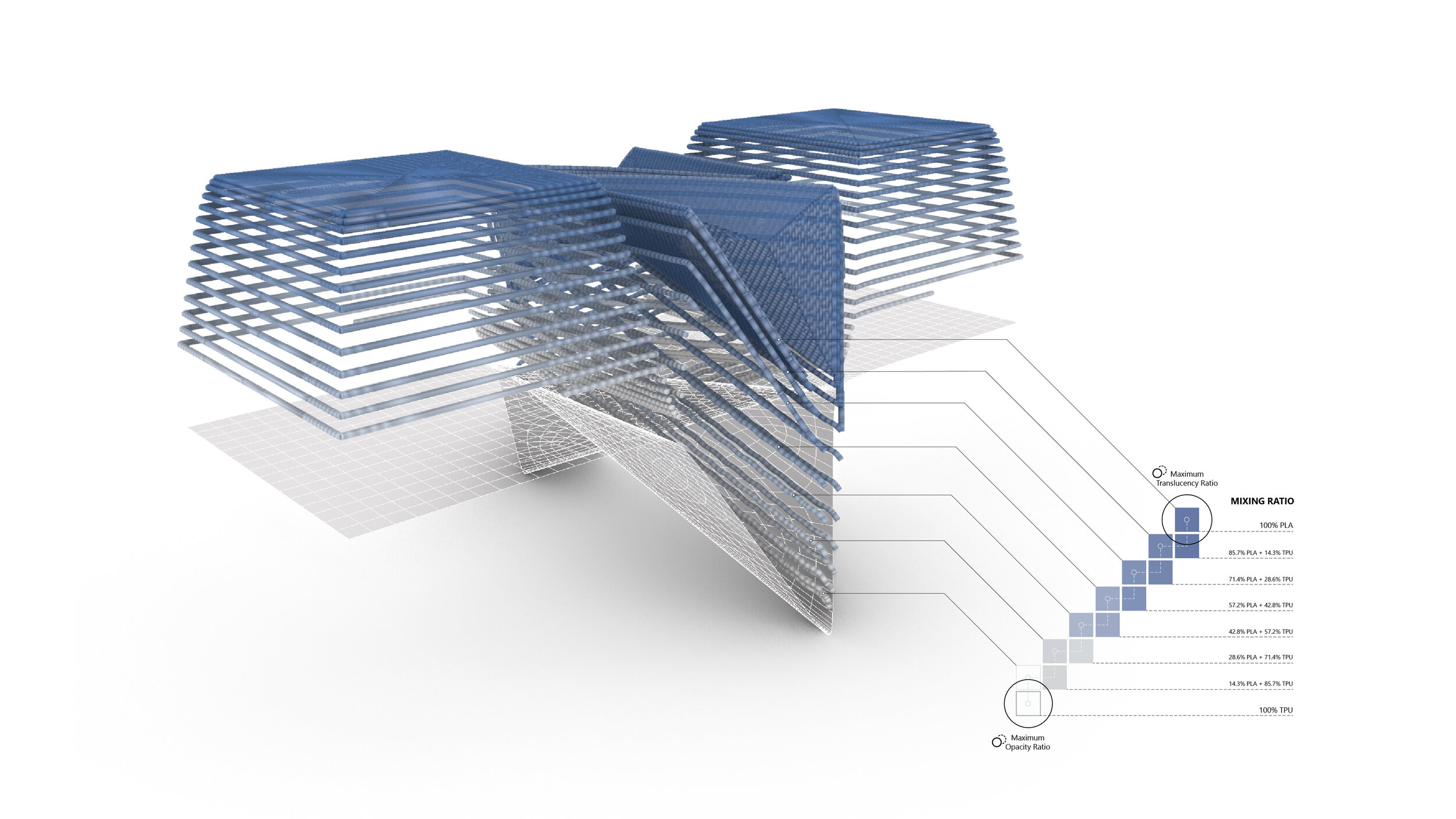

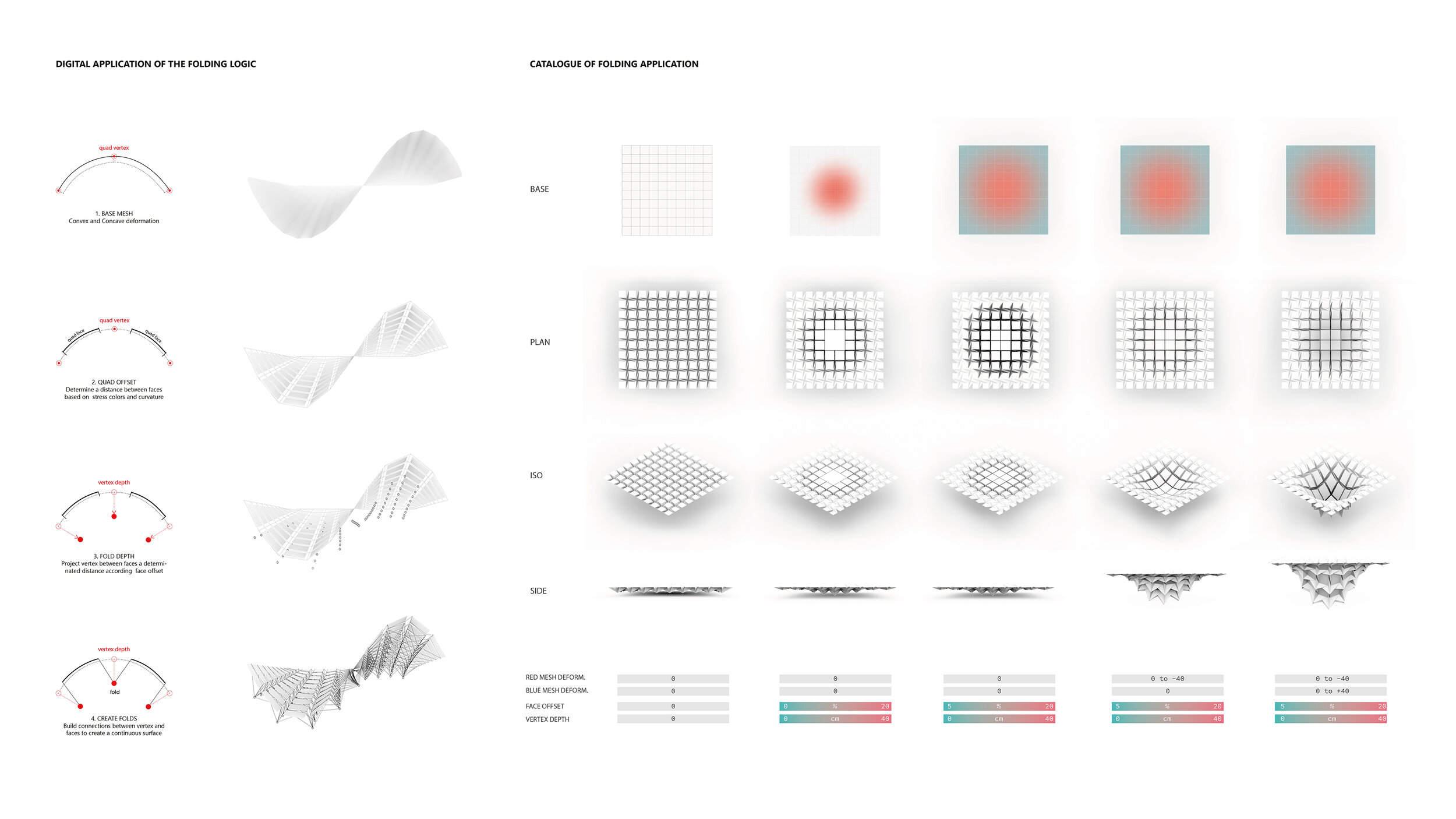

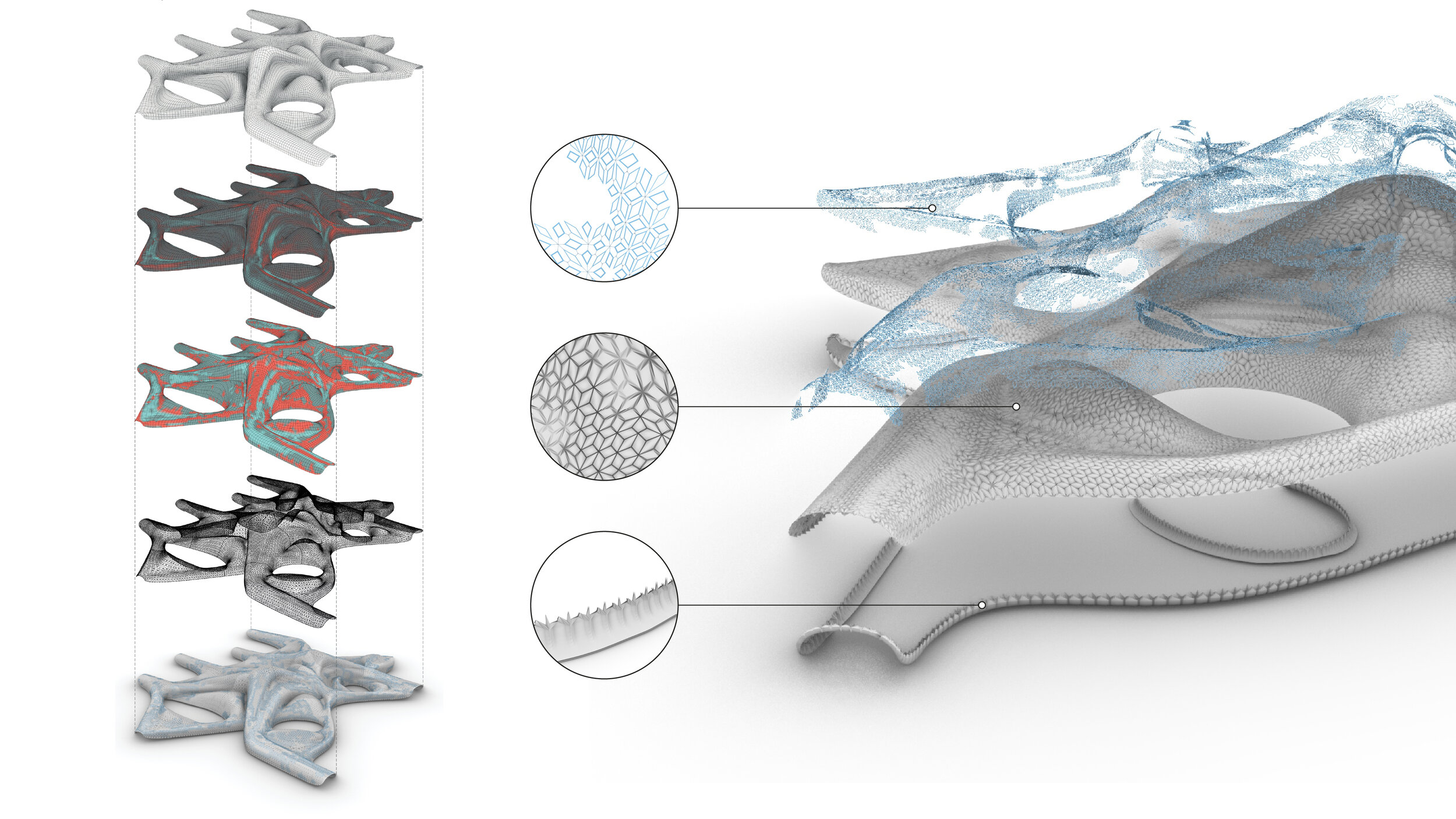

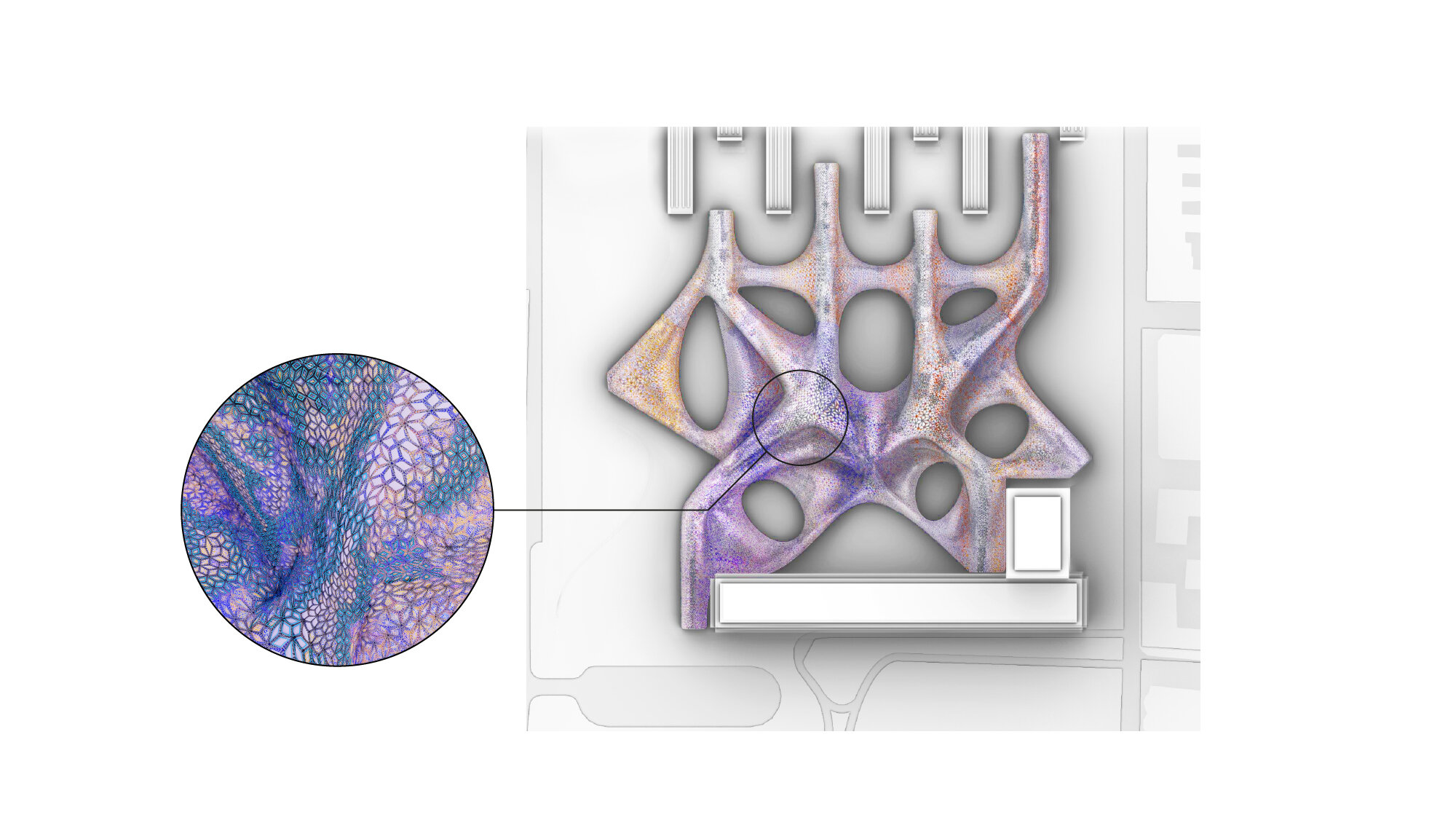

A model unifying design, materiality, structural requirements and fabrication through digital tools is often missing from contemporary design-and-build methods. As a result, a comprehensive material system, Metaplas, was developed, able to be fabricated ecologically, ethically while exhibiting economic benefits through a decentralised system. Beginning with an extensive material research, two recyclable thermoplastics were identified for their potential in achieving a foldable multi-material panel that is 3D-printed flat and made three-dimensional through an integrated patterning system.

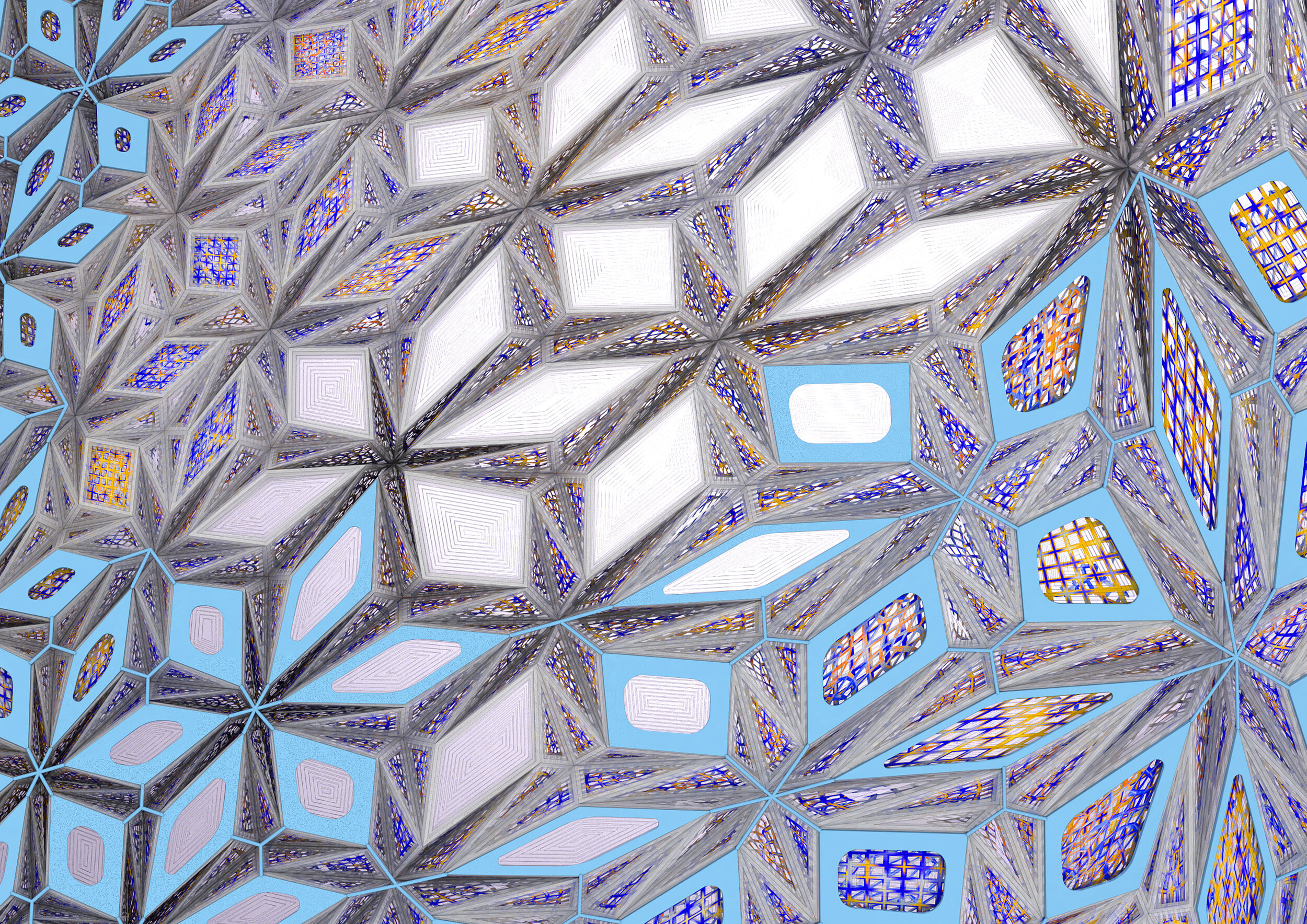

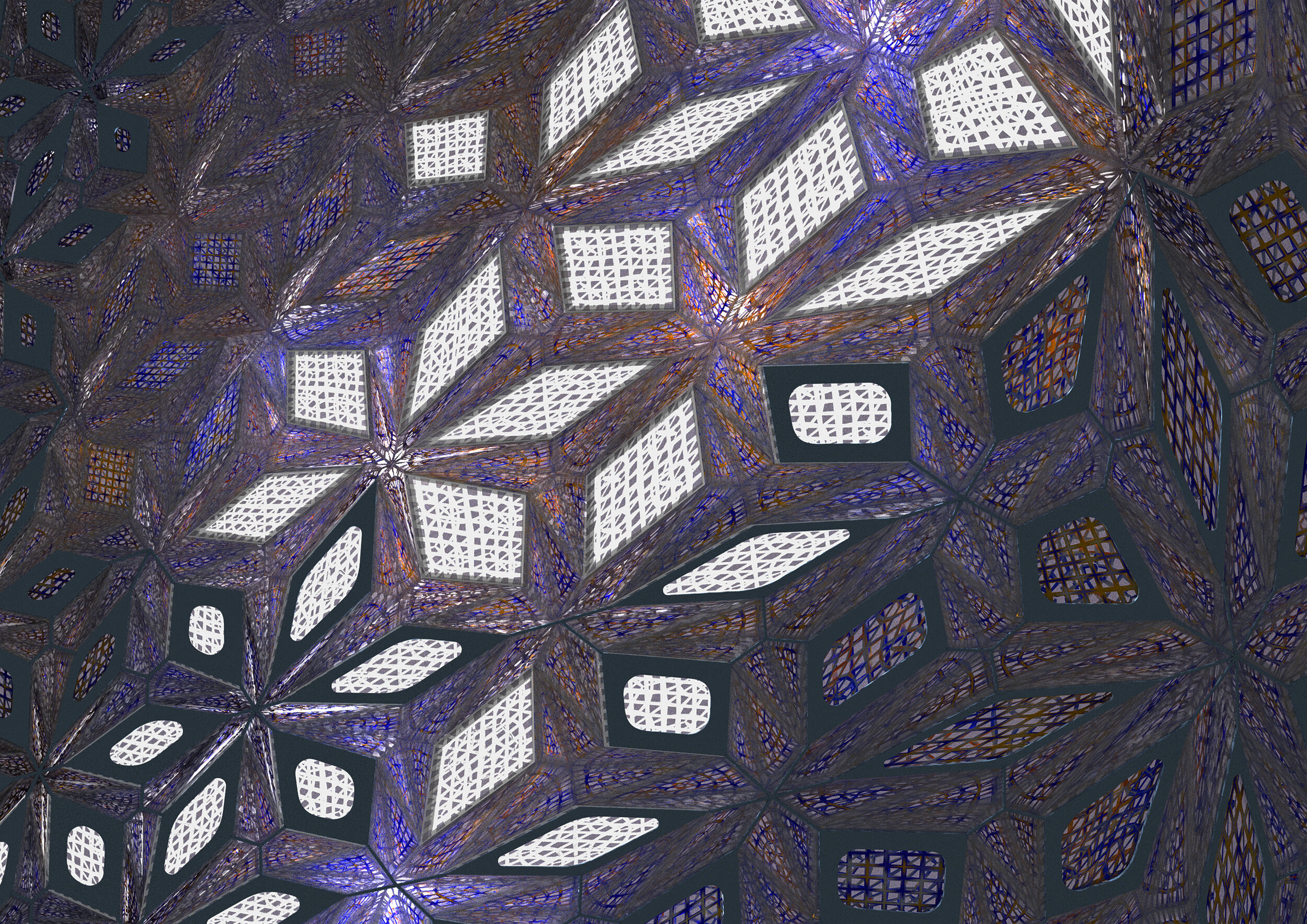

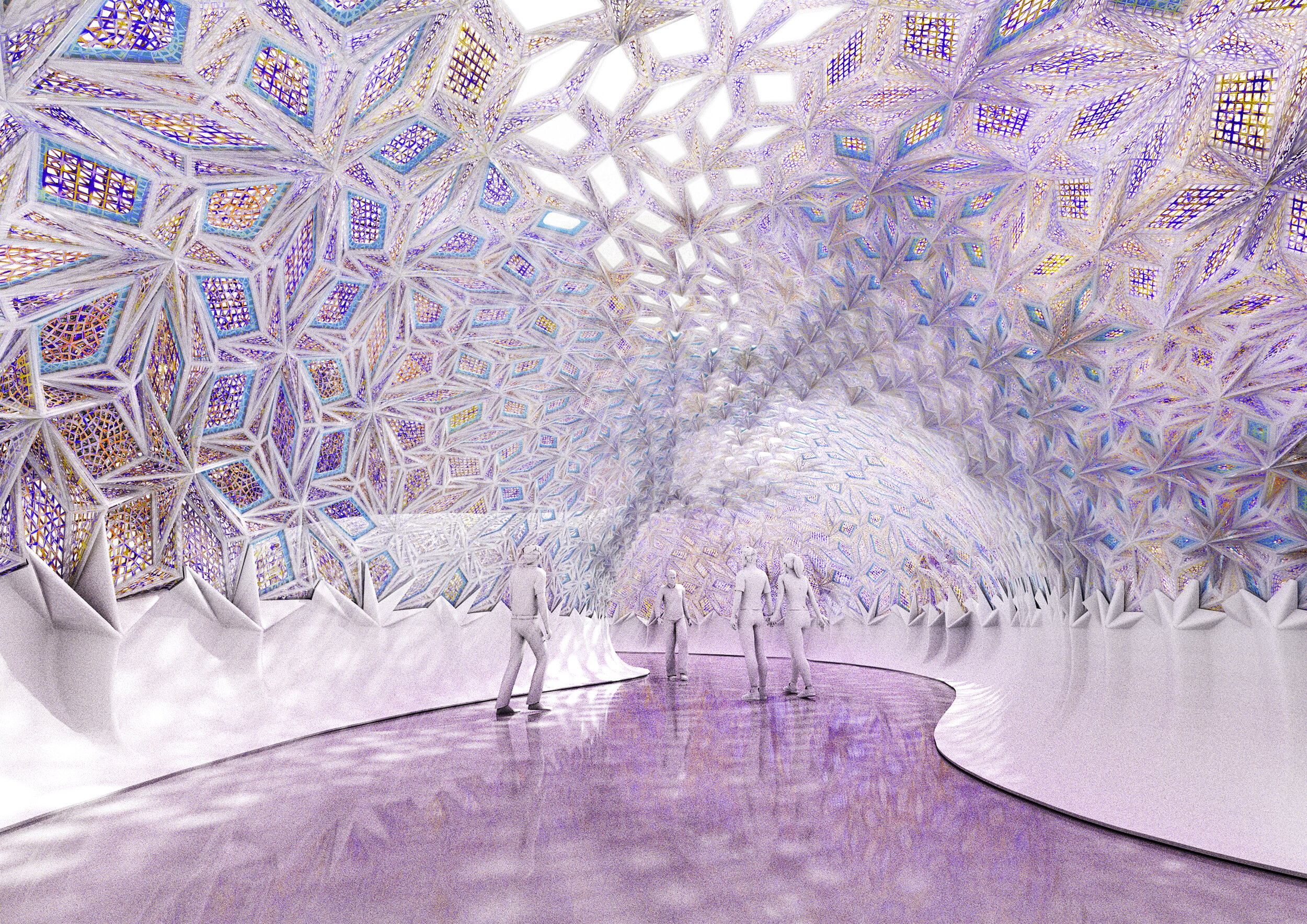

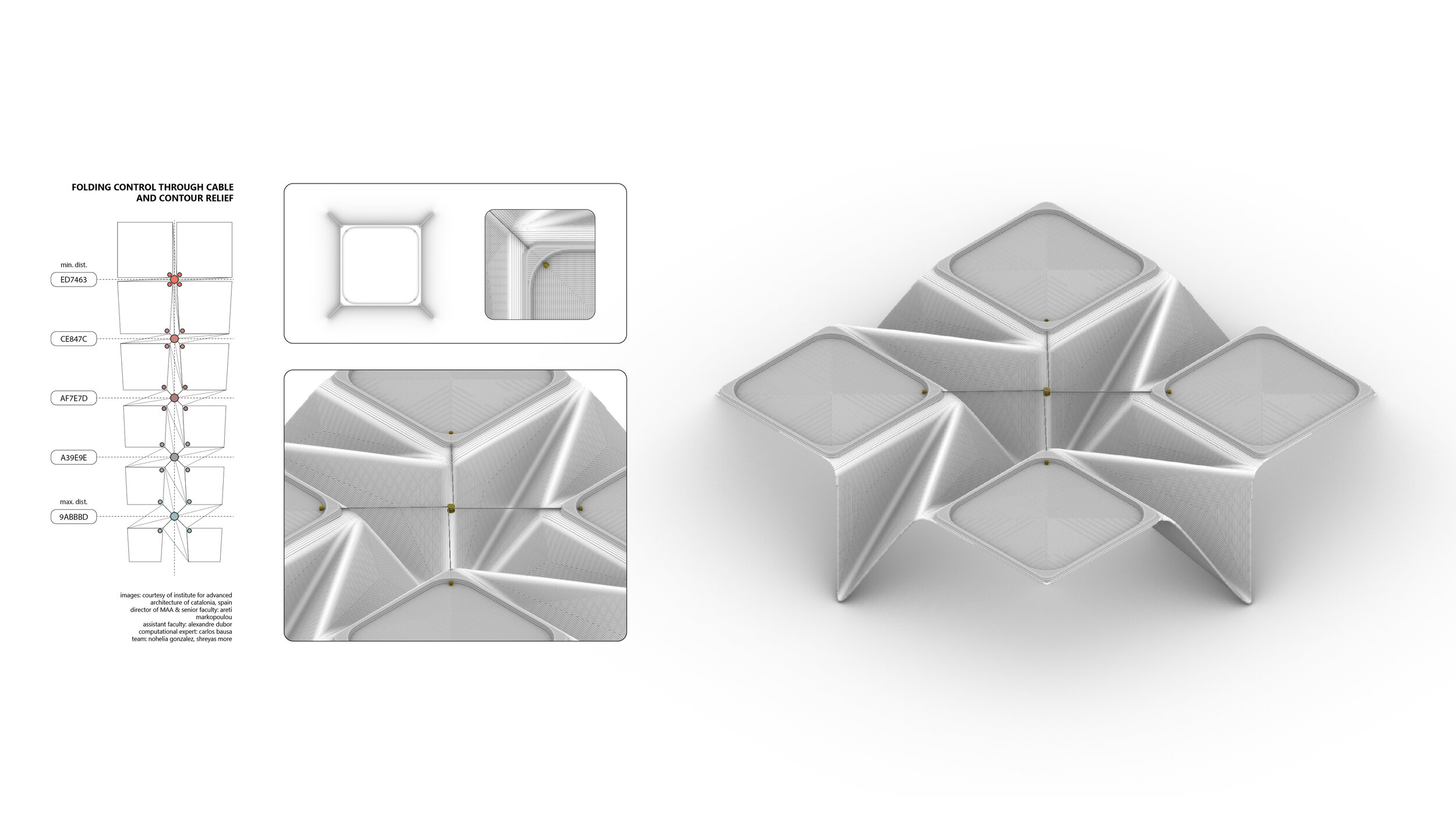

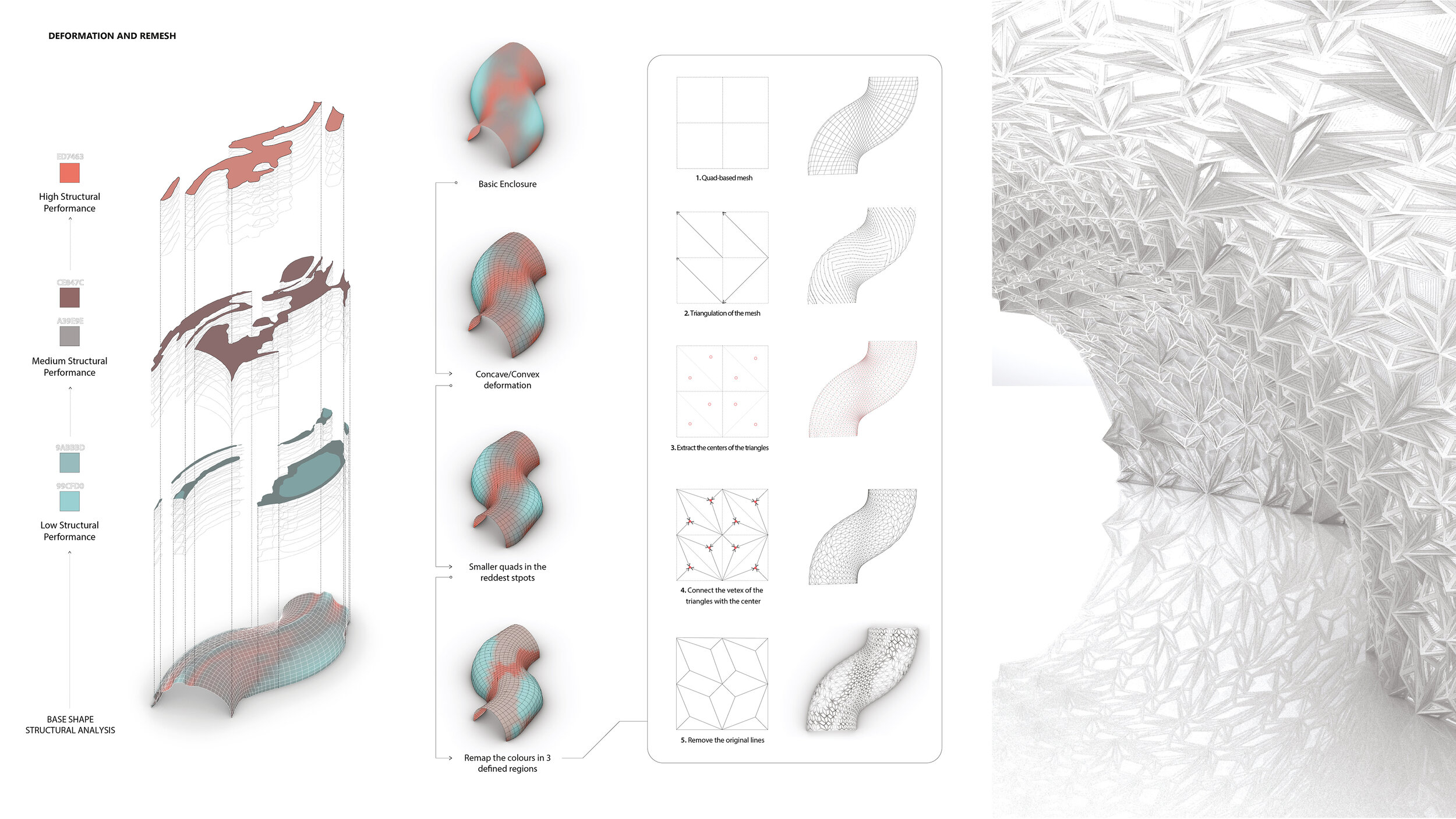

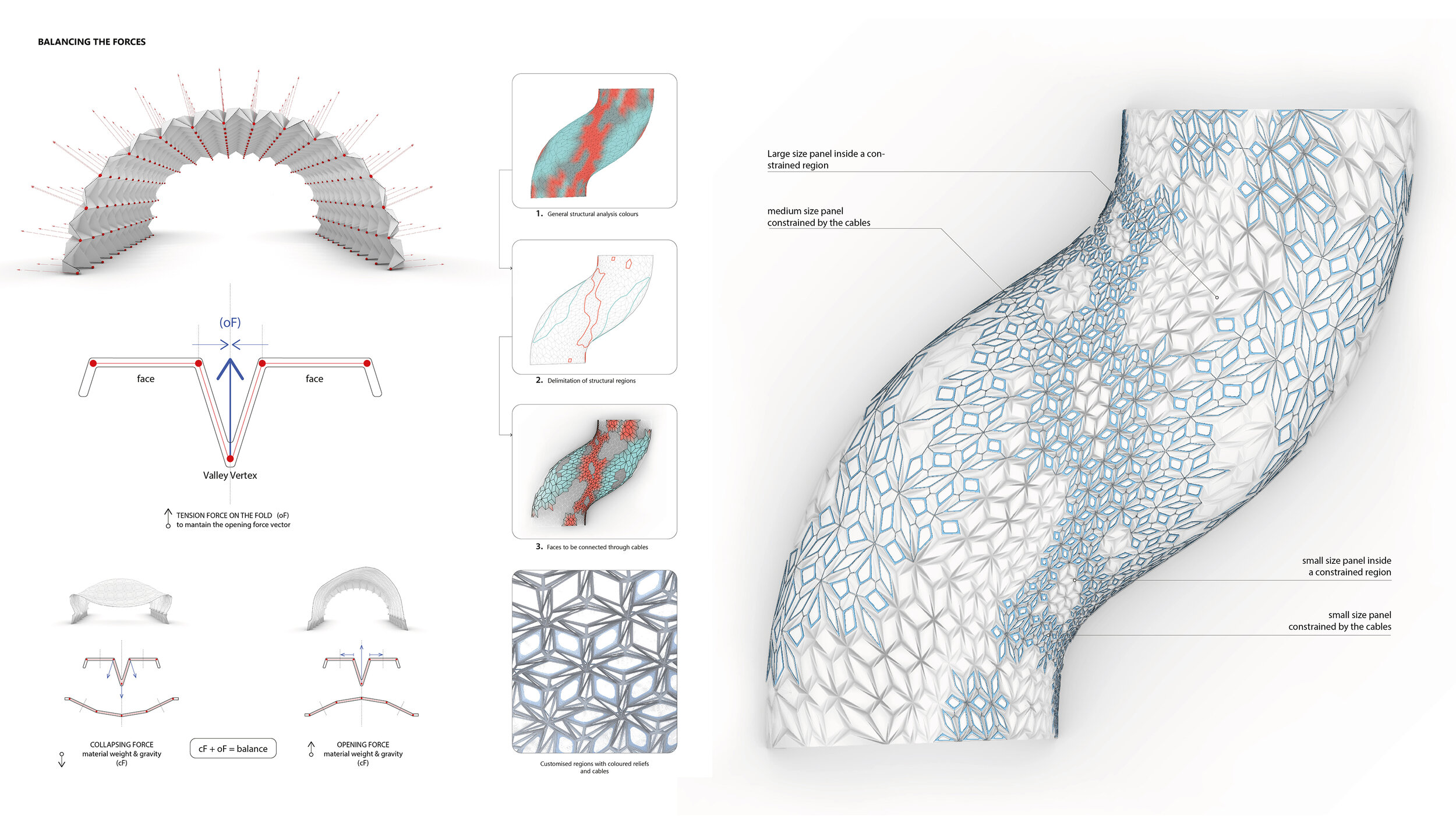

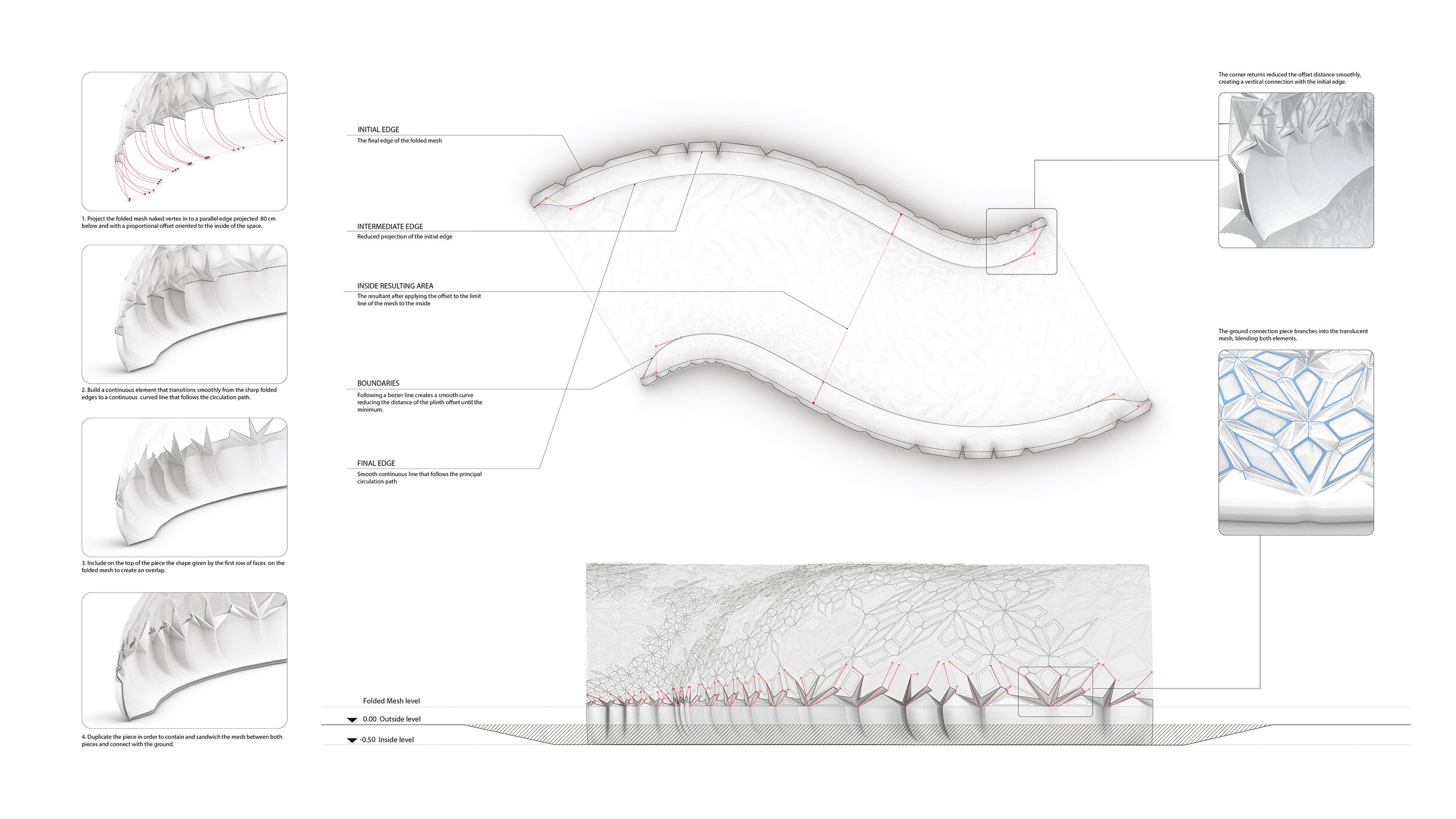

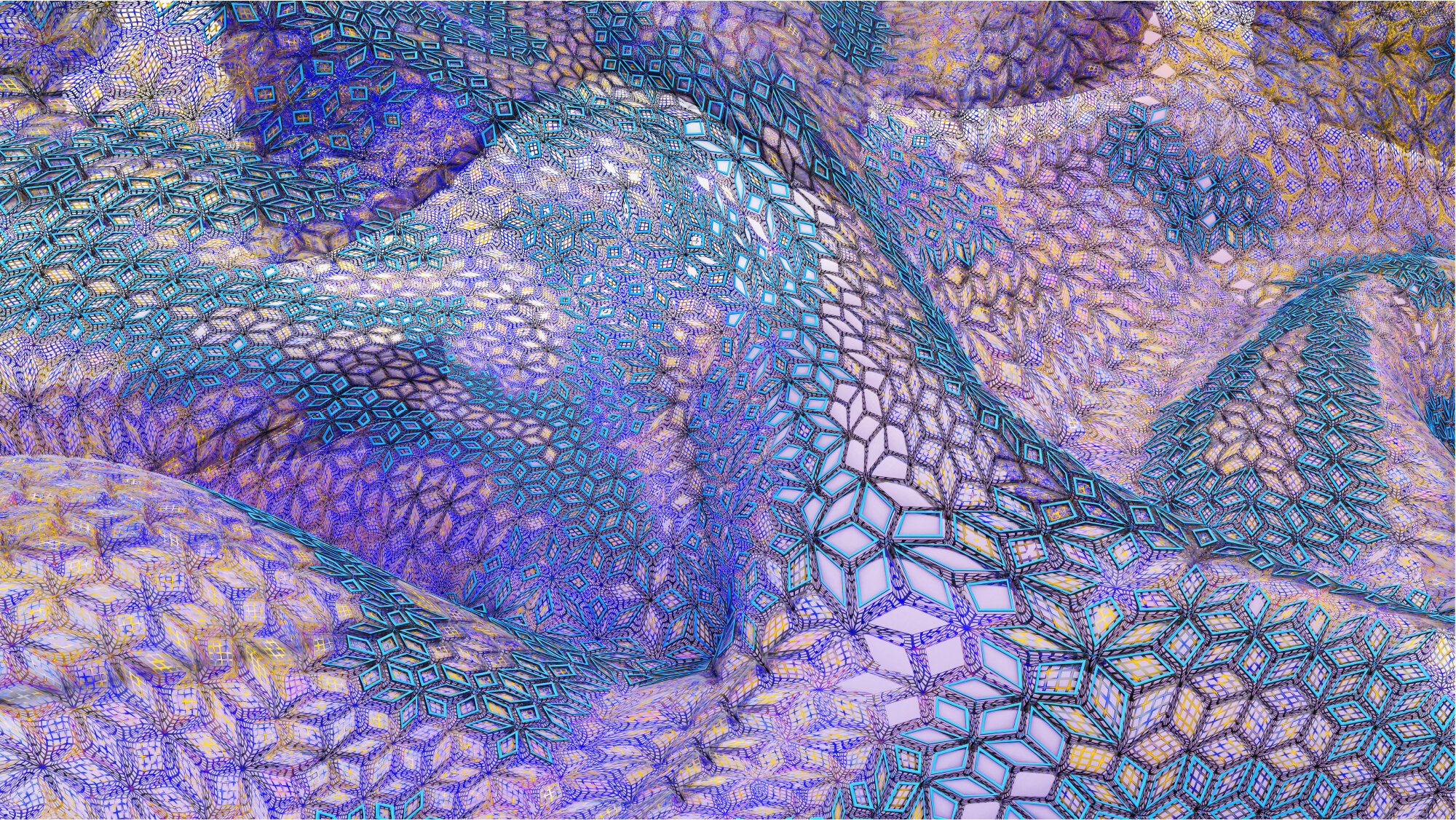

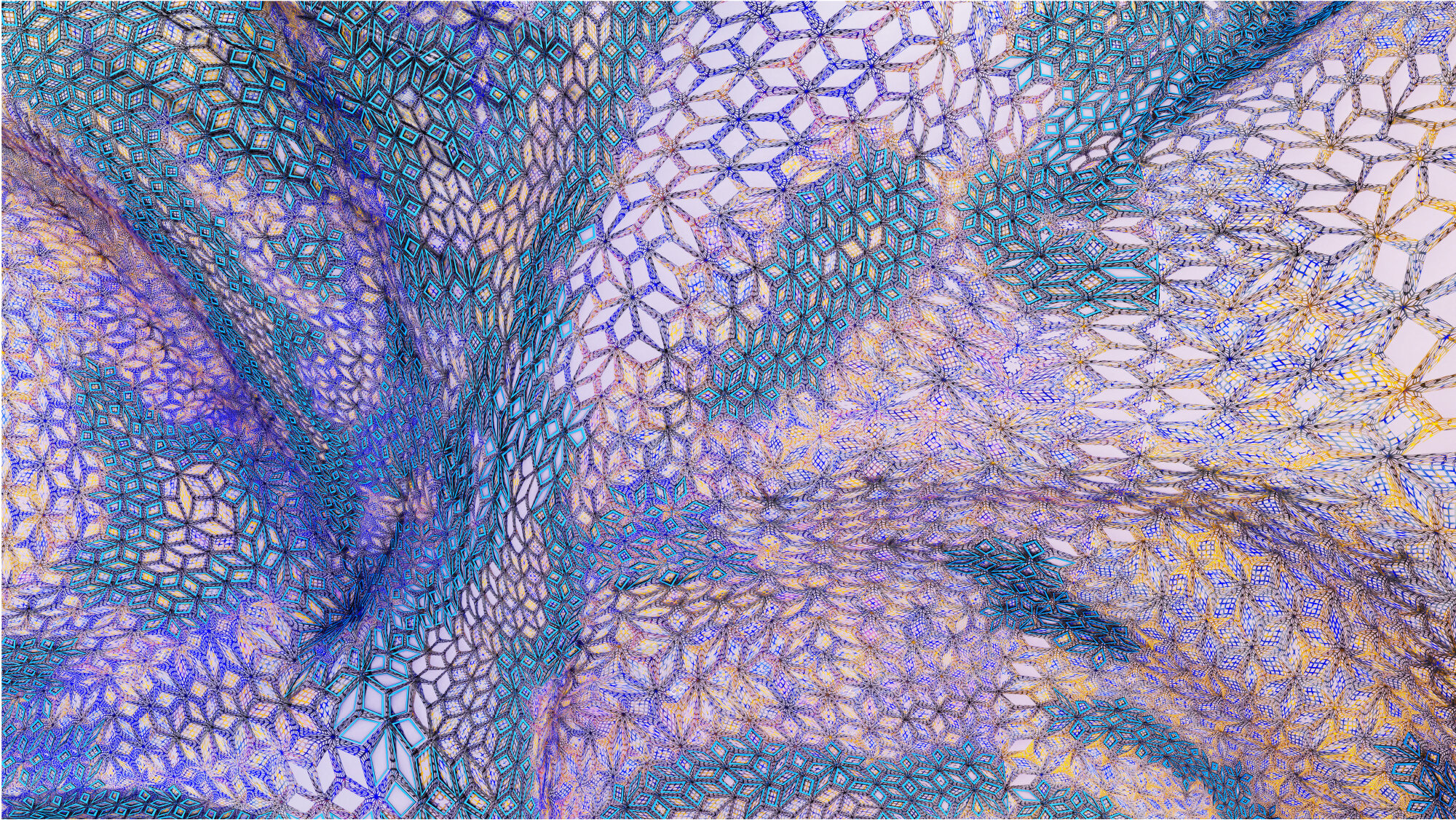

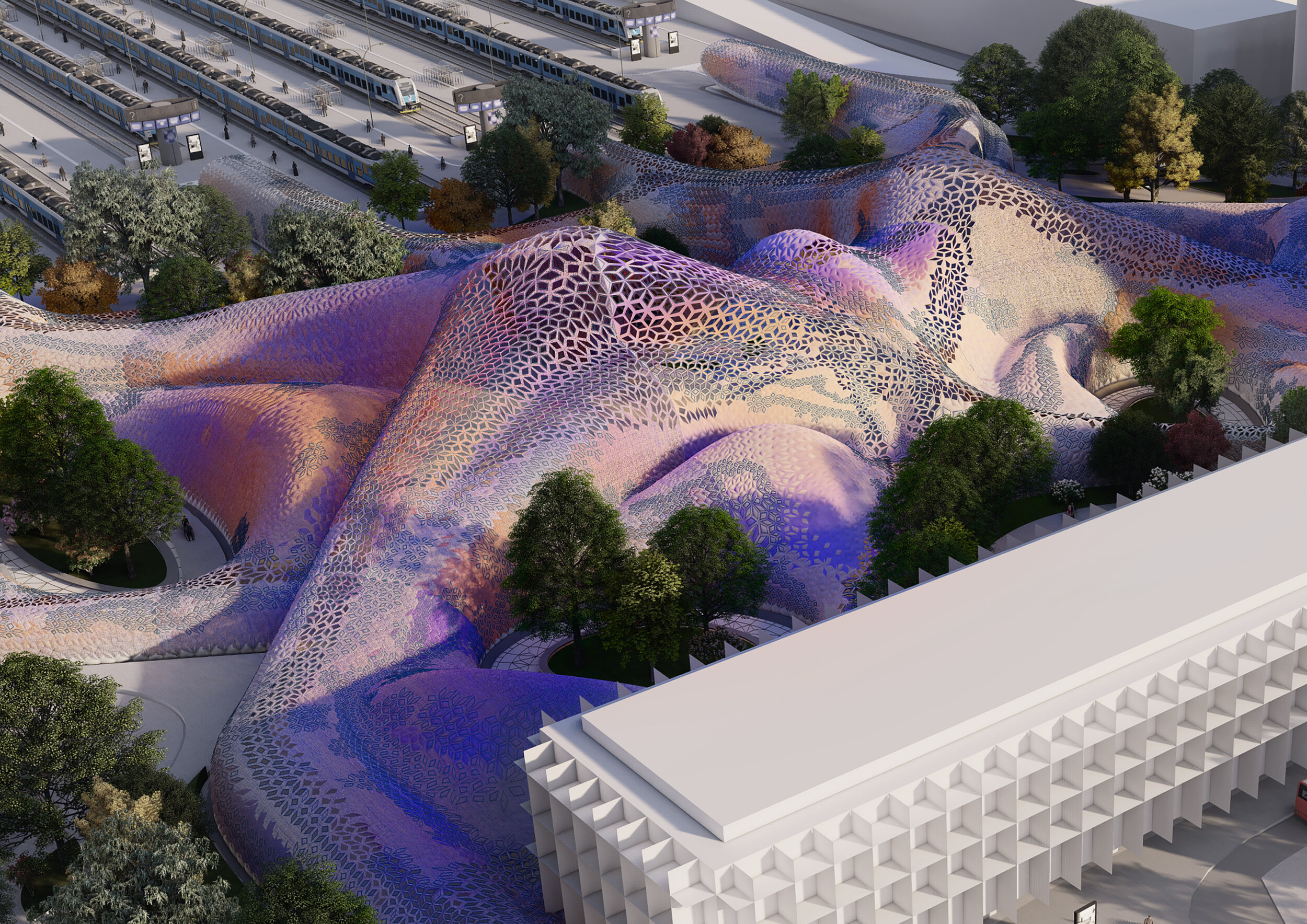

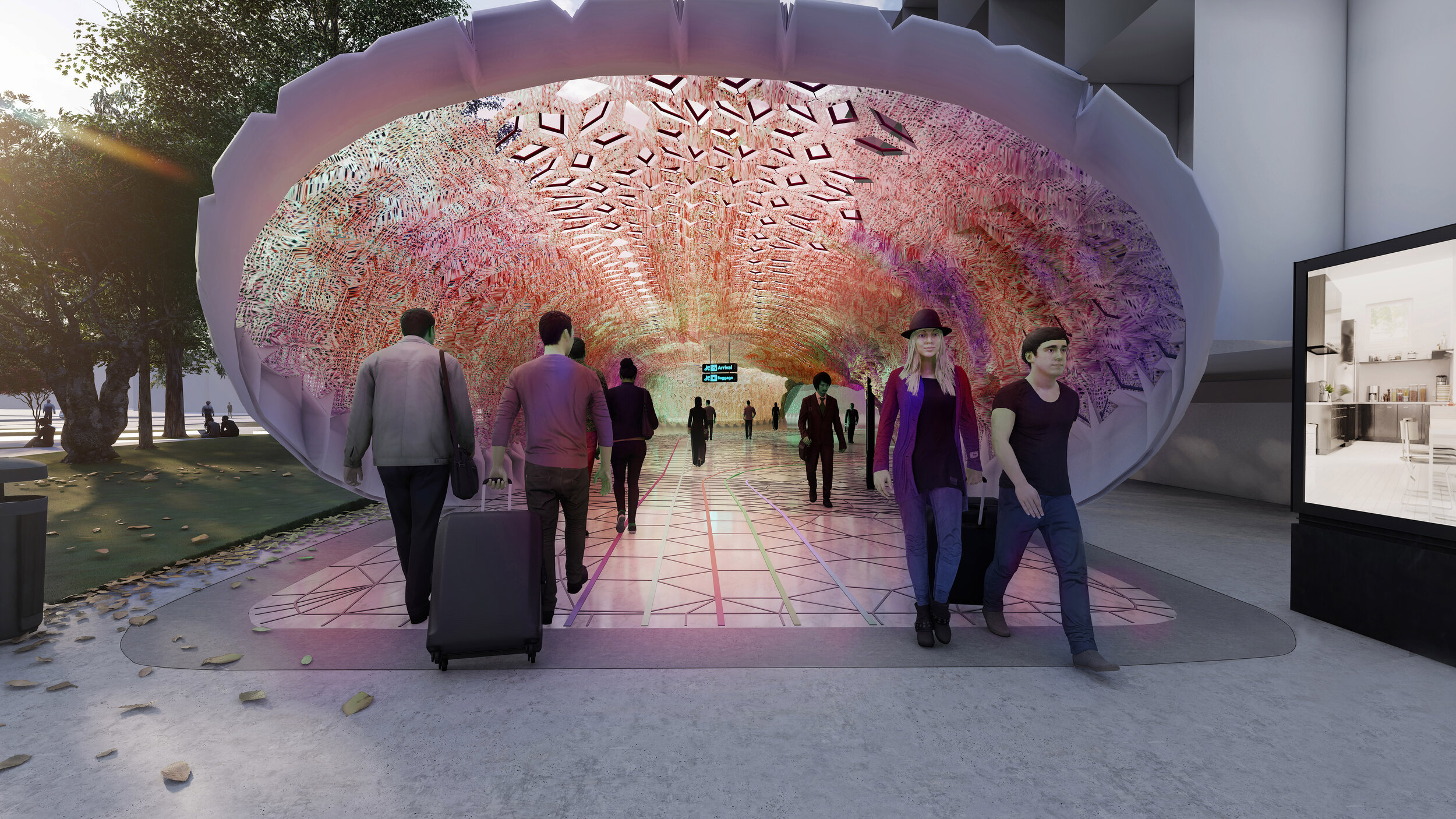

Folding as a geometric tool was enhanced through a customised process involving structural analysis prior to folding. Areas that require the most structure are densest in folds, while areas that are intrinsically structural are sparser. The folds are secured through a cable system and a clip-lock mechanism, easing assembly, disassembly and maintenance. Moreover, an embedded micro-pattern within the system achieves passive control over the lighting temperature of spaces.

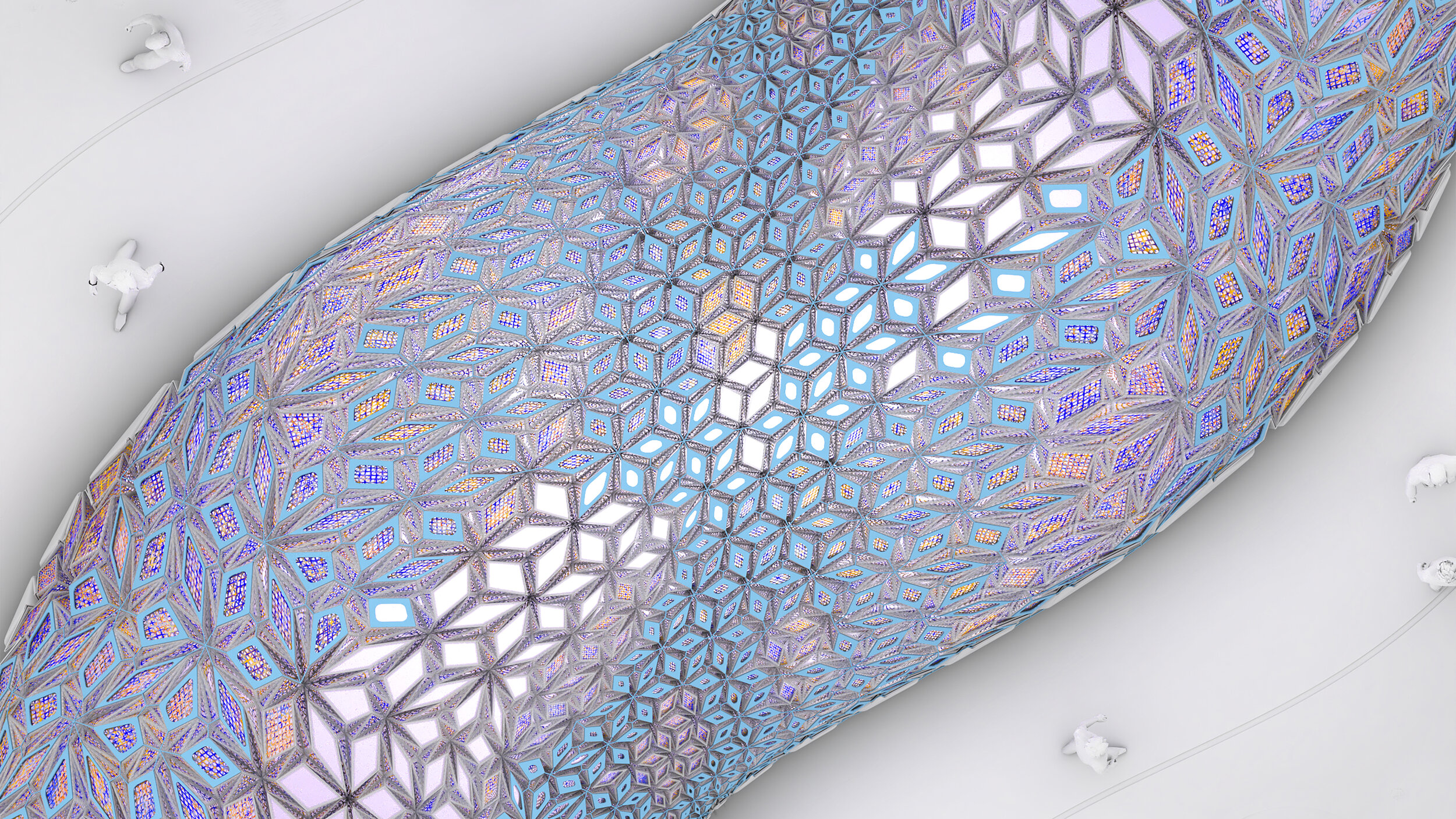

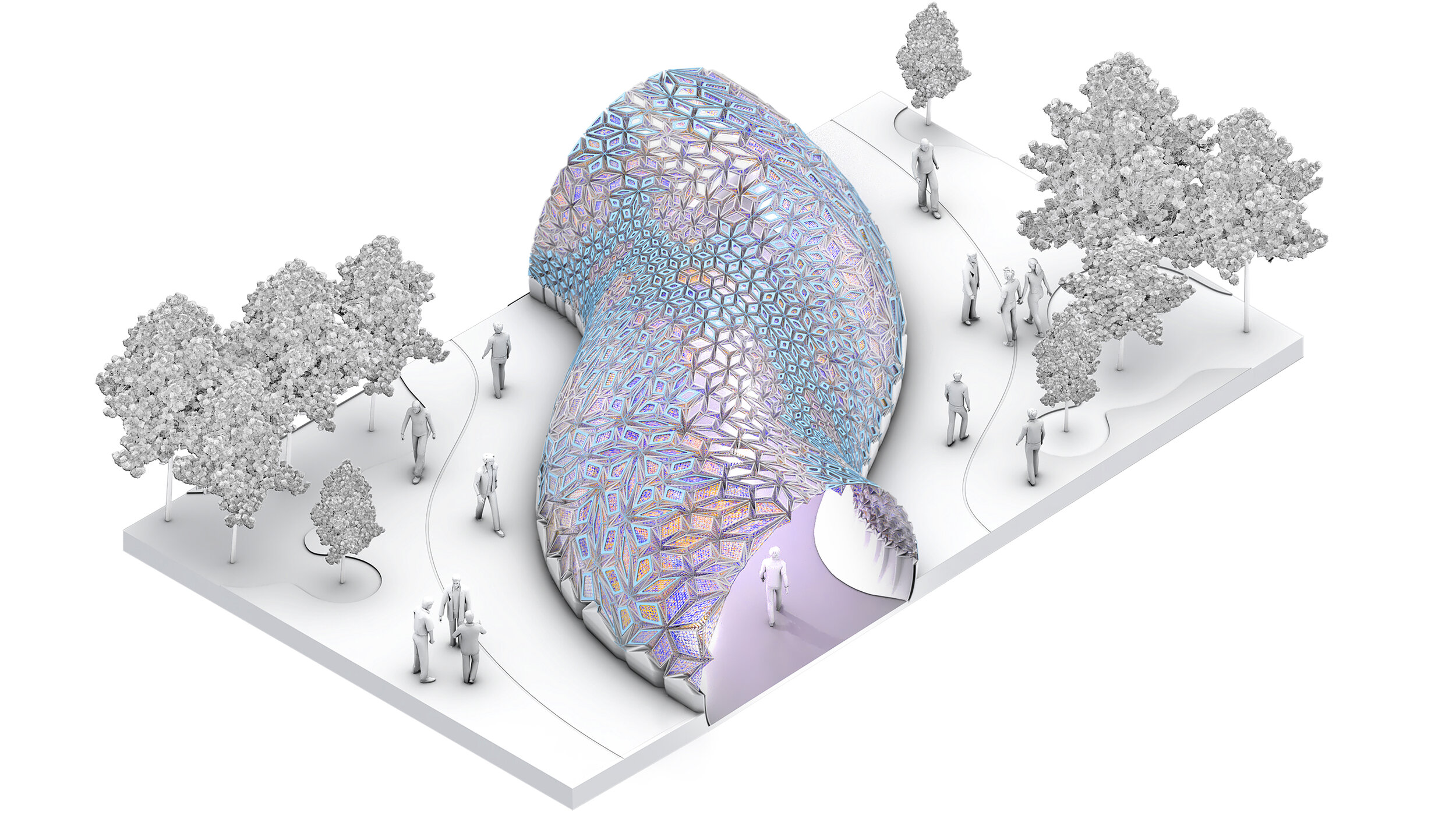

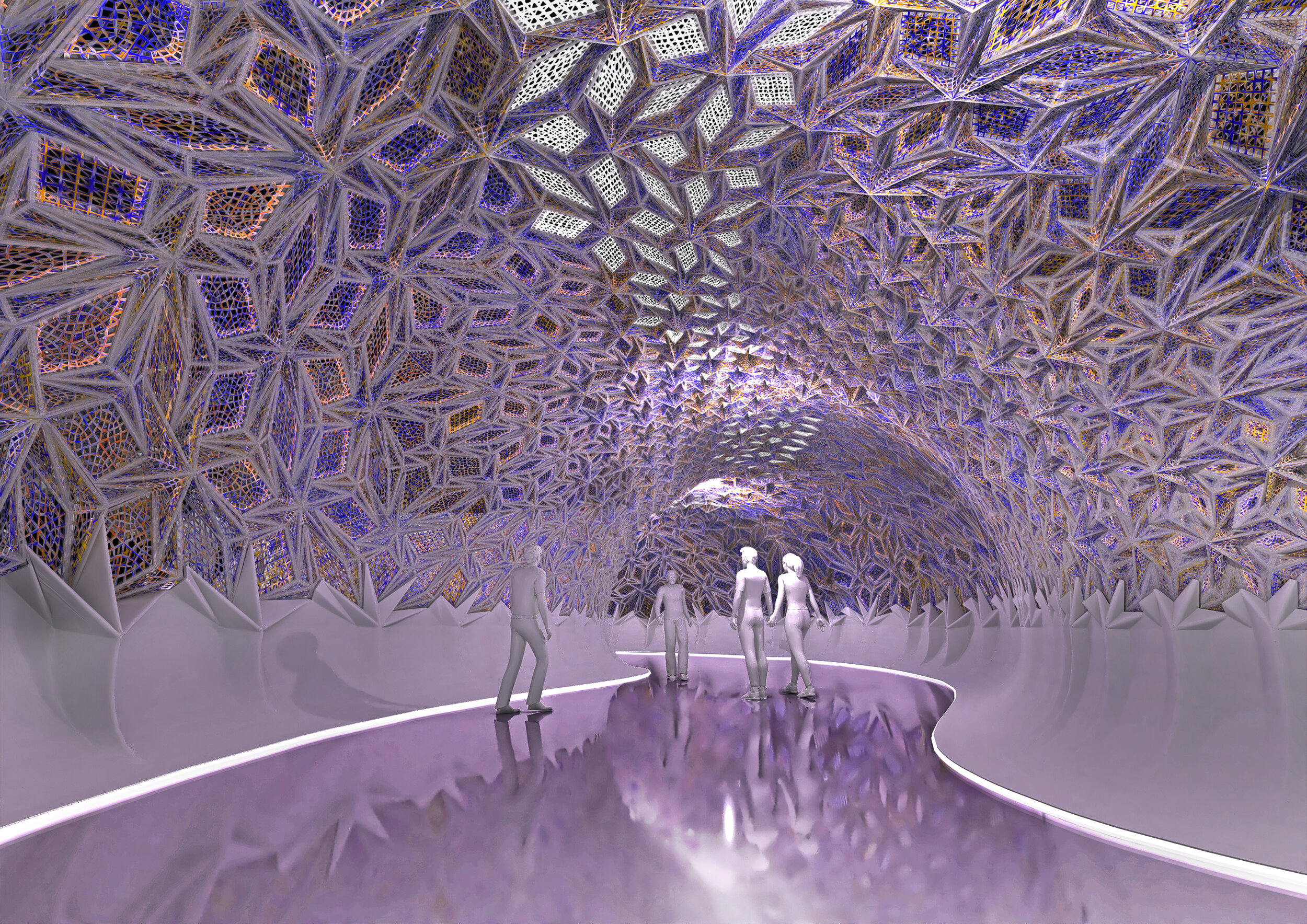

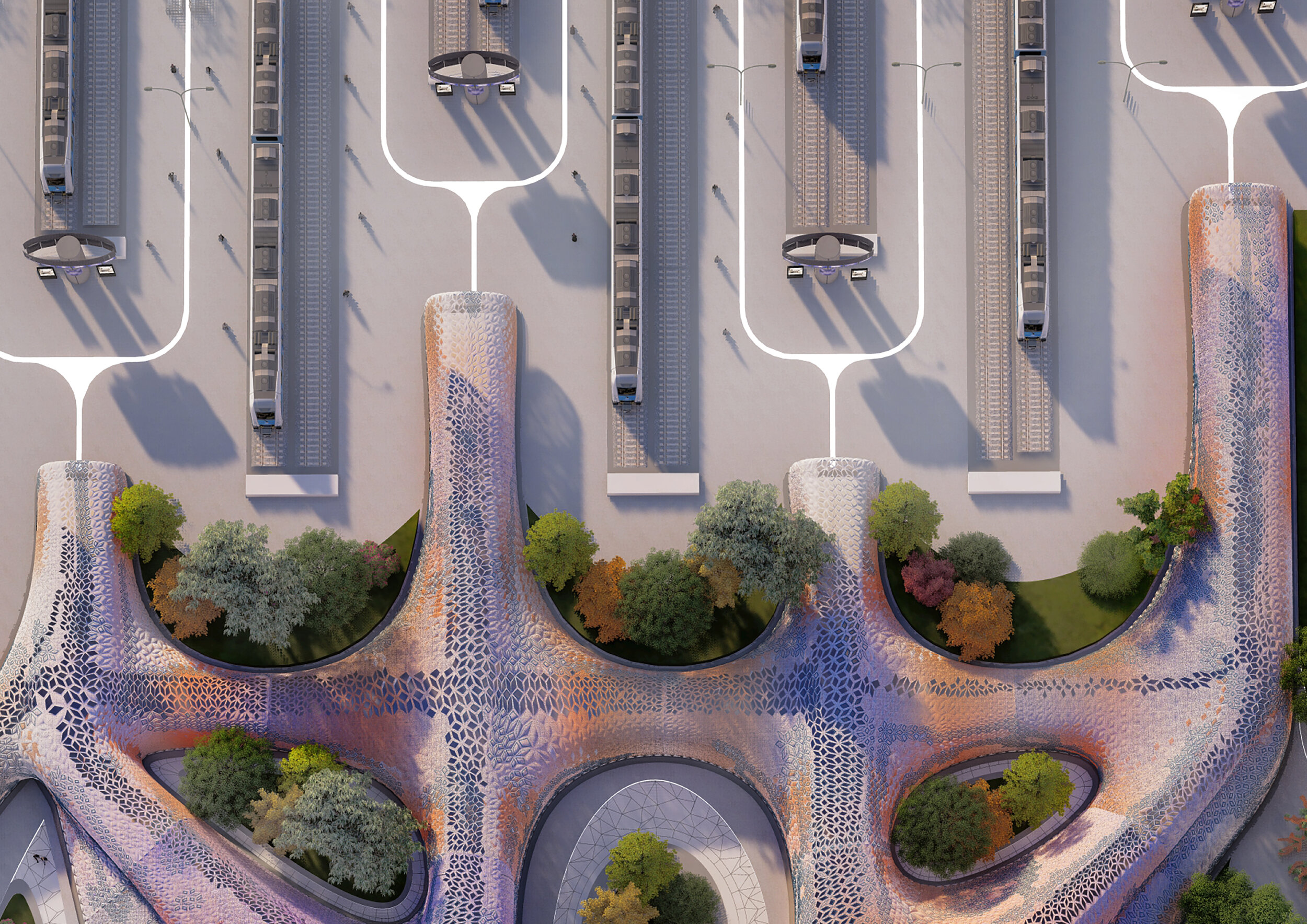

Euston station’s new canopy is the large-scale architectural scenario for Metaplas. A decentralised fabrication approach is established by identifying and mapping scattered recycling and 3D printing facilities within a radius from the site. The panels are fabricated in these facilities, thereby boosting the local economy and breaking the economic displacement and polarisation caused by traditional centralised productions.

Teammates: Betty Chavez Angeles, Prapatsorn Lertluechachai, Wisnu Hardiansyah

Tutors: Kostas Grigoriadis and Martina Rosati

Research Cluster 8 (RC8), Master in Architectural Design (M.Arch), Bartlett School of Architecture, UCL.